Rother And Shook 1999

Rother shook 1999 define a structured approach for improving a value stream.

Rother and shook 1999. Manufacturing facilities rother and shook 1999 p. The task of generating a. Learning to see m rother j shook summary learning to see written by mike rother and john shook is the book to read for value stream design. In every lean implementation it is important to understand the current process design and the way the design influences the flow of products through the factory.

Main focus is on waste reduction and inventory control. A fifo lane is a controlled inventory point between two process steps which has a maximum number of products in it 1 and a fixed sequence in which products are taken out of the inventory 2 rother shook 1999. An action guide for managers engineers and production associates which received a shingo award in 2003 mike s recent books are toyota kata mcgraw hill toyota kata culture and. Free shipping on qualifying offers.

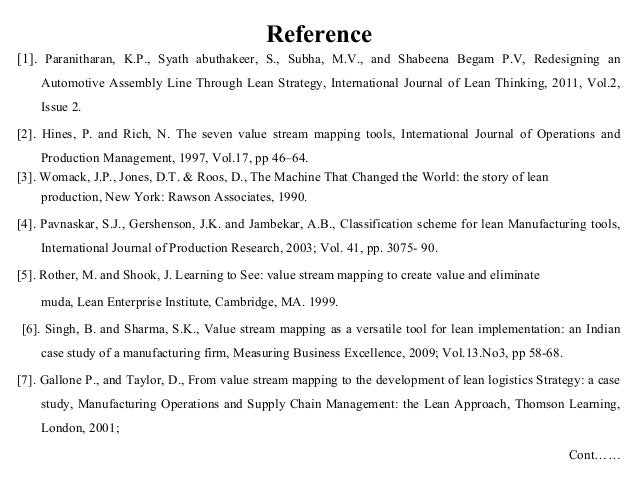

Value stream mapping to add value and eliminate muda. The second step is to construct a current state map for the product value stream using information gathered from the actual production process. Mike is co author of two groundbreaking lei workbooks learning to see. Shook learning to see value stream mapping to create value and eliminate muda learning enterprise institute brookline 1999.

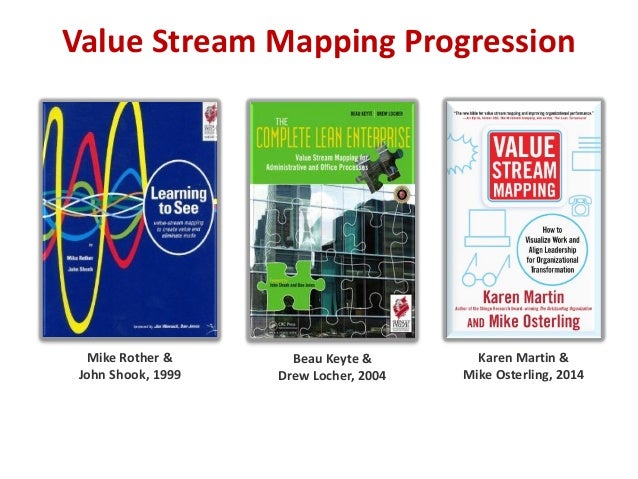

The challenge lies in seeing it. Value stream mapping s roots mike rother john shook 1999 beau keyte drew locher 2004 whenever there is a product for a customer there is a value stream. The predetermined maximum means that upstream machines stop production when there the maximum is reached. This method s relevant aim is the reduction of the wastes through improvement of the logistics processes.

The first step is to identify relevant product families and select one as the target. Firstly this was published in learning to see in 1999 by mike rother john shook 7.